Known for its acres of greenery, picturesque lake and old-world architecture, Sentul West takes centre stage once again with its most enigmatic building to date.AM talks to YTL Land & Development Berhad (YTL Land) director Yeoh Pei Teeng and Ar Edric Choo Poo Liang of Choo Poo Liang Architect (CPLA) on Kuala Lumpur’s newest icon of adaptive reuse.

Interview by Nizar Musa

YPT

When we came onboard, micropile substructure works had already begun. The overall four-storey massing had also been set. But on this kind of project, there are always many things to resolve. YTL Land requested us to relook and refine the design, and we proposed various options for their comparison and selection.

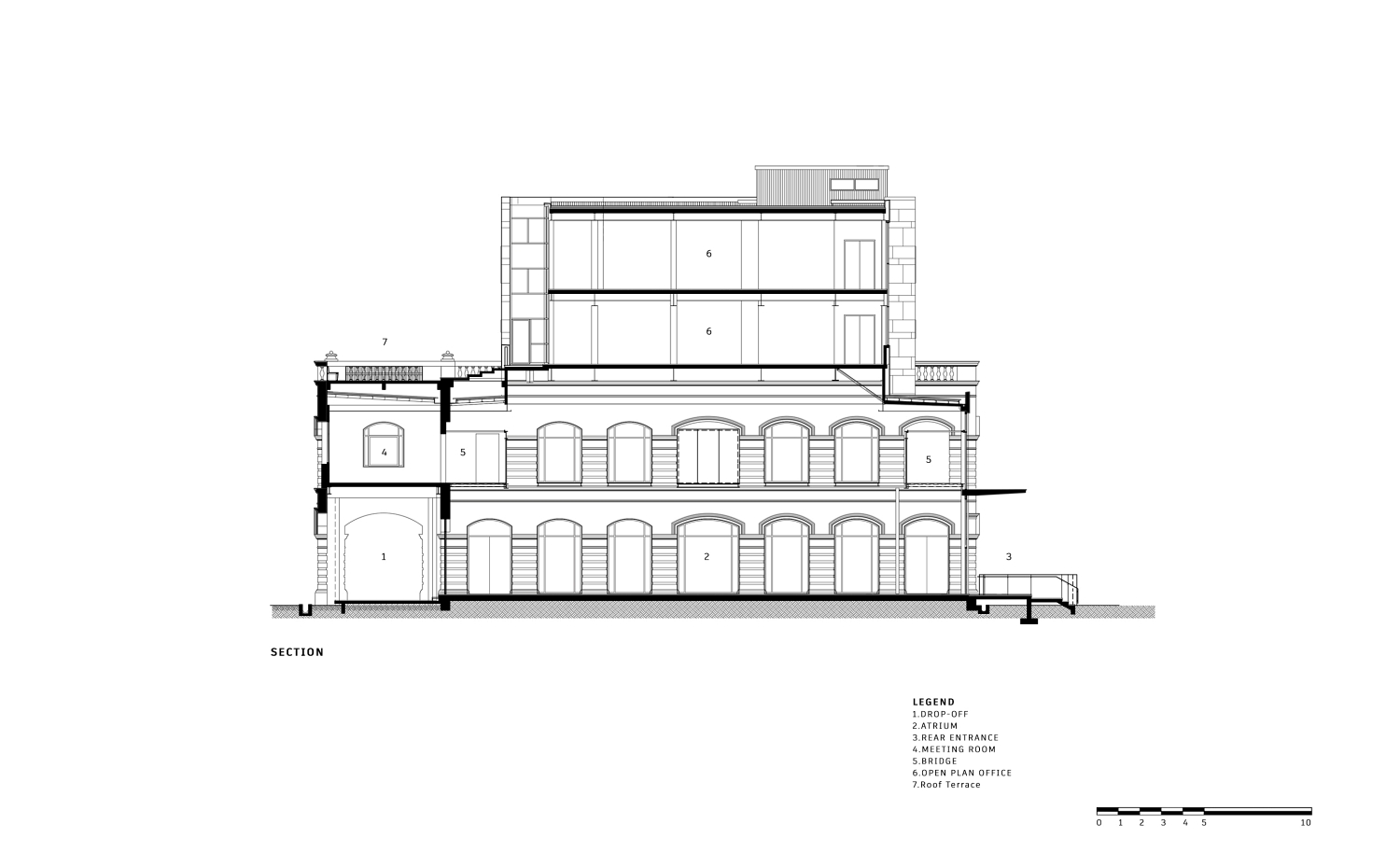

Sentul Works’ two-storey atrium, for example, was something we reintroduced together with the original drop-off area. The idea was to create an arrival experience that showcases the integration of old and new.

That juxtaposition of modern structure on heritage building is fraught with risks aesthetic and constructional in nature. Nevertheless, it is a bold decision that has paid off in some style.

Materiality was important to us for those reasons. From the very beginning, we spent a lot of time sourcing references and benchmark projects that had a similar aesthetic to our building. That’s when I came across the CaixaForum Madrid by Herzog & de Meuron, which I felt was quite interesting in its balance and contrast of old and new architectures.

To reactivate and reconstruct the carcass of the existing building, we took cues from the industrial past of Sentul’s old railway complex. A lot of details went into the building design, from the selection of materials executed through glass, steel frames, Corten steel and concrete to finishes like natural stone and timber. There were also changes along the way as Sentul Works isn’t meant to be your typical KL office building.

EC

The engineering, from a constructional perspective, was quite interesting. The structural engineer had devised a steel framing system where the columns shot straight up from the micropile foundations to the third storey, totally bypassing the existing building. Which meant the upper floors were entirely supported by the micropiles with no load transfer between old and new structures.

We also have a mezzanine floor to level 1 that is hung from the floor above. When we introduced the idea of the mezzanine, it was to enhance the double-volume space experience. Since construction was ongoing and the structural loads had already been calculated from the ground up, it was decided to hang the mezzanine from the top, using rods to achieve a delicate look.

EC

Convincing the client of your design, to begin with, is very important. That means a certain level of visualisation is necessary. With the Corten steel façades, we studied the original design and identified that Sentul Works lies at the centre of YTL Land’s properties like Sentul Depot, The Fennel, the park. We came up with a concept to map three grids onto the elevations, comprising of structural column lines, the old building façade grids and colonial-era English bond brickwork patterns. The idea was to create a relationship between the new and existing entities. From that mapping, we derived window openings, pop-out windows, and balconies to frame the views surrounding Sentul Works, and capture the genius loci of the site. Recessing the windows, which came from Pei Teeng’s input, also helped add depth to the façades.

Sometimes it’s not about (design) drawings and presentations, but more of onsite decision-making. Pei Teeng and I would most of the time take site walks and appraise the ongoing works. As you would expect, there would be many eroded or missing parts to the existing shell after a hundred years. So onsite resolution is important especially for restoration projects when the existing building cannot be precisely model in 3D. The interfaces between old and new had to be identified and resolved during the site walk, which we did.

YPT

EC

One of the biggest challenges is the brickwork itself. Pei Teeng’s idea was to strip the layer of weathered plaster off the existing building and expose the colonial-era brickwork. We then expanded that idea by having the new extension-work bricks be also laid in English bond. We preselected types of bricks that closely matched the original, with some cut at the site to achieve the same brick-lay aesthetic. Erecting the new brickwork alone took a whole year, especially with the brick pointing that was protruded and had to be done layer by layer by skilled workers.

Our redesigned staircase was also challenging. We opted to fold 10mm thick steel plate in steps welded to solid 8mm thick steel balustrades. The balustrade tops were further folded into handrails, to prevent them from warping and also to conceal the LED light strip. These unitized stairs were fabricated in the factory, and then at site hoisted into position before being welded into place. What was achieved is a floating staircase without any visible stringer or supporting structure. All you see are the folded treads, risers, and balustrades as a single piece, which is unique in terms of architecture combined with good engineering design.

EC

YPT

The collaborative environment we had over the last few years – between my colleagues in the design team, CPLA, our project consultants – was one of diverse backgrounds and expertise. I was constantly inspired by what came out of that teamwork, the lessons learnt were invaluable in my growth as a leader. It’s an experience that does make you reflect on how you led the project, the challenges and responsibilities that came with that leadership. Above all, I am blessed to have worked with a great team who saw the project to its completion.

I remember looking at this old building years ago, astounded by its rugged colonial beauty there among the trees. I had a lot of ideas for it, one of them a contemporary office for the younger generation. Today, I can proudly say that has been accomplished.