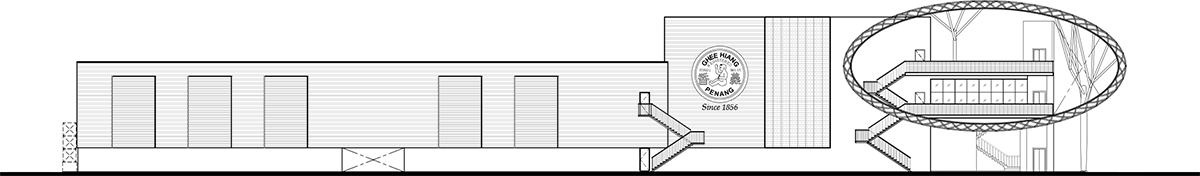

Nestled at the cornerstone of a traffic circus within Penang Science Park North in Simpang Ampat, is Ghee Hiang Manufacturing Company Sdn Bhd’s newest industrial facility. Ghee Hiang, a heritage brand and cultural icon spanning almost 170 years, started off producing traditional pastries before becoming synonymous with teel seed oil; a gift normally bestowed on mothers who are in confinement. Its logo, a waving infant inside a red circle, is instantly identifiable. Ghee Hiang gained its success through many years of careful expansion and growth and as such, the theme for this facility was to reflect the ideology of natural growth.

This ideology is prominent on a site scale, as the 2 to 3-storey facility sits humbly, fittingly, yet distinctively within its industrial context. Both roofscape and streetscape portray a universal architectural language, with the extensive use of Zincalume® steel (AZ150). The façade is also a unified collage of texture and colour, complemented by building elements that match the steel.

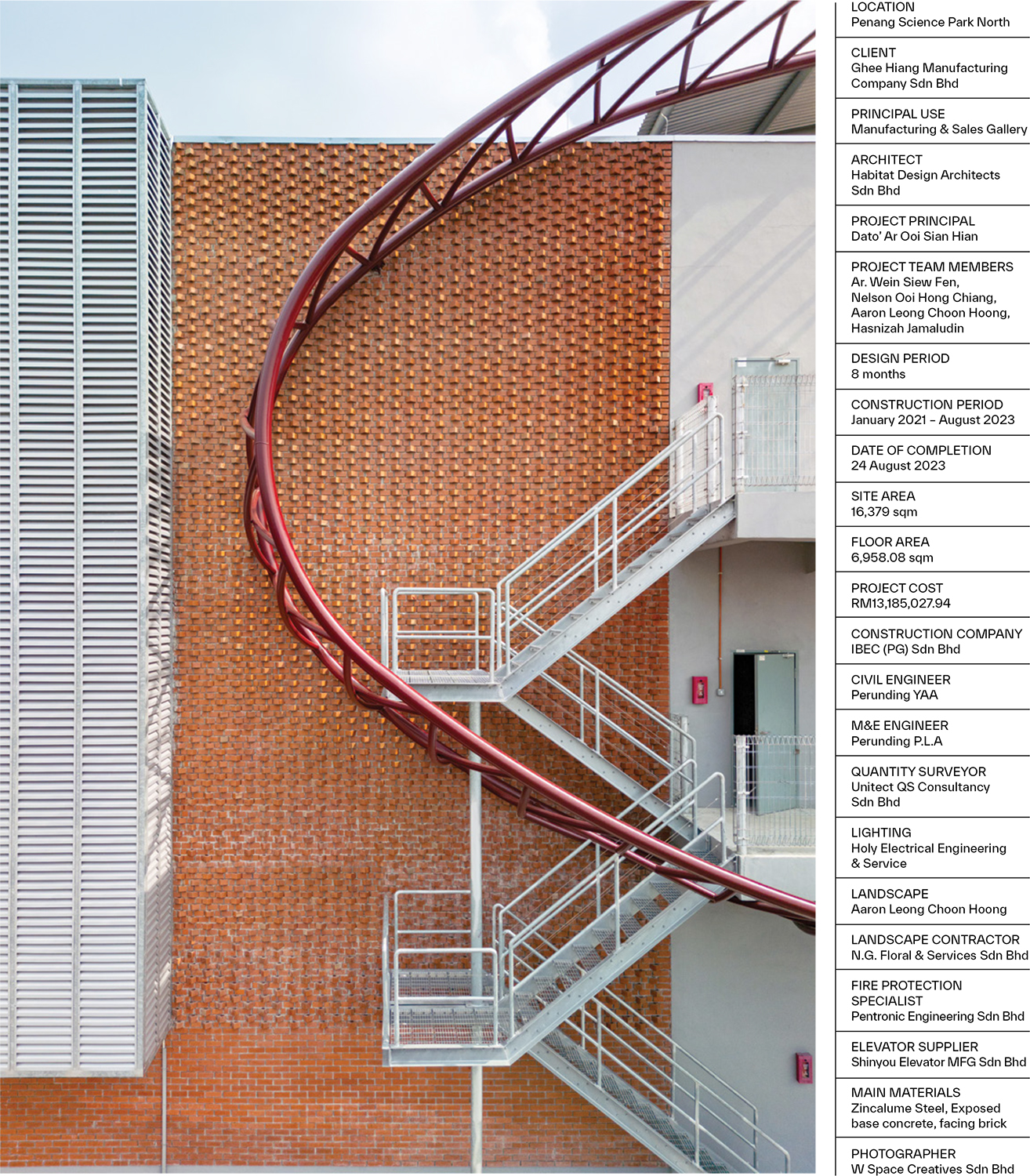

A captivating design statement is displayed by two steel halos, painted in red and interconnected by a curvaceous roof at the front building. Inspired by the kernel of the teel seed, these halos symbolise longevity and infinity, and they are instantly recognisable from the streetscape.

The construction of this 4-acre facility was fuelled by the increasing global demand for Ghee Hiang’s teel seed oil. The facility is separated into two parts; the first is a 3-storey building, enclosed by a roof curvature made of Zincalume® steel, that is open to the elements yet shielded by functional customised louvres, mirroring the canopy layer of the forests. A production area and office space occupy the first two levels, with a recreation and event space on the top floor.

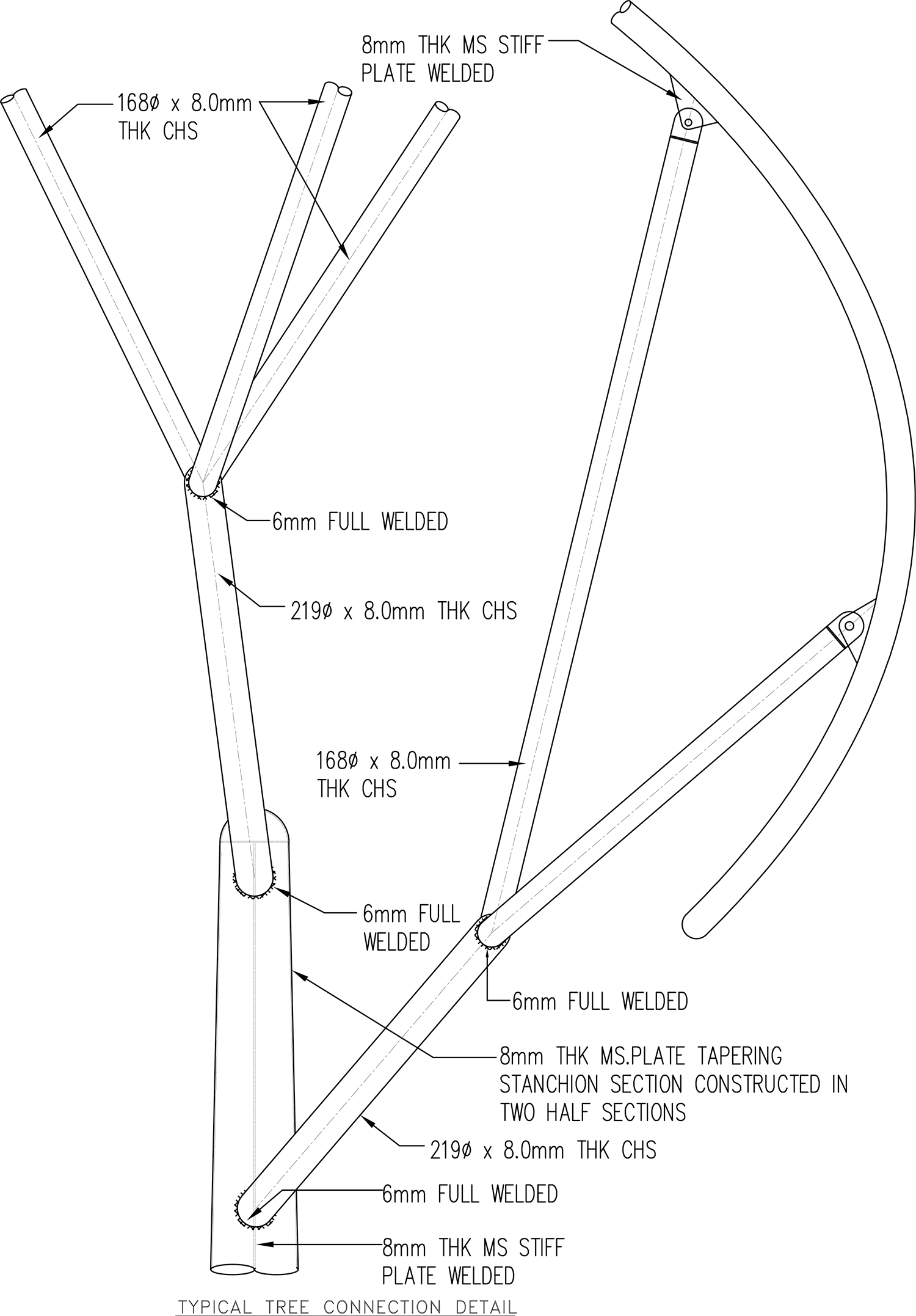

Three gigantic steel columns symbolising the Sesamum indicum tree form the support for the curved roof. At the rear, two single-storey buildings divided by a corridor for forklifts, are warehouses for raw materials and finished goods from the production line. The second part of the facility is where the finished goods are packed, and stored before being shipped out to customers worldwide.

As the facility is for the production of food, building materials specified and used have to comply with Good Management Practices (GMP) requirements to ensure the safety and quality of the end product, as well as for ease of maintenance. The steel roof of the warehouse is left bare to ensure that the raw material can dry out, aided with natural ventilation via 3 angled bays of fixed louvres, custom-made in Zincalume® steel.

The entire facility is finished with Zincalume® wall cladding with exposed bare concrete and facing brick that demonstrates the honest approach to the manufacturing process. The patterned facing brick contrasts pleasantly with the selected cladding and different tones and shadows are noticed at various times of the day. With time, a natural patina will coat the surface of the brick façade.

Inspired by the kernel of the teel seed, these halos symbolise longevity and infinity, and they are instantly recognisable from the streetscape.

Rainwater is drained through carefully sculptured stainless steel gutters and rainwater downpipes. The form of the logistic buildings is elementary thereby ensuring the texture, finishes and colour of the materials are allowed to shine. Expanded galvanized wire, normally used as fencing, is shaped to act as a barrier at the balconies.

As a footnote, the entire facility was constructed and completed during the COVID-19 times, when there were strict restrictions on the logistics of raw materials and skilled labour was scarce. As the form of the buildings is unpretentious, extra effort was undertaken to ensure the cladding, louvres and extrusions were all precisely dovetailed during installation. The completion of this facility demonstrates the design team’s endeavour to strive towards excellence and innovation.